Fueling Innovation: Pressure Vessels

Project Description

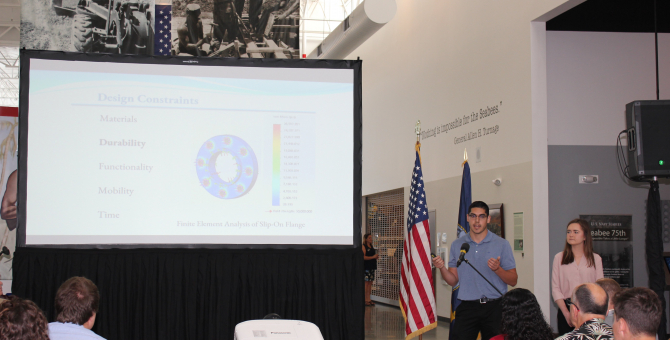

Our project is to design, build, and test a small-scale fuel pipeline, using non destructive testing techniques. The main goals of this project are to hydrostatically test our pipeline and have it become a testing and training platform for future Petroleum, Oils, & Lubricants engineers. The current solution is to train engineers at an existing fuel pipeline, which can lead to safety risks due to a lack of previous exposure to operating procedures. Some of the design requirements and constraints that we faced were related to the materials, durability, mobility, and time. The pressure vessel and components are made of steel. The strength of the vessel was simulated using Finite Element Analysis and analyzed with the Von Mises criterion. For mobility, we have a cart to support our pressure vessel. Completing each step in a timely manner was our last major constraint.Our proposed solution includes a three-foot long, a four-inch diameter, steel pressure vessel with an attached testing tree. The tree includes an assembly of pipes, pressure gauges, valves, and hoses. For the hydrostatic test, we will pump water into our vessel through this tree and record data using a flow meter, pressure gauge, and dead weight tester. Using theoretical calculations, the procedure focused on hydrostatically testing our vessel at 100 psi. The vessel will be pressurized for varying periods of time, allowing us to determine the integrity of the pipe and any points of leakage. Our final product will allow Petroleum, Oils, & Lubricants engineers to learn how to use non destructive testing equipment both properly and effectively.