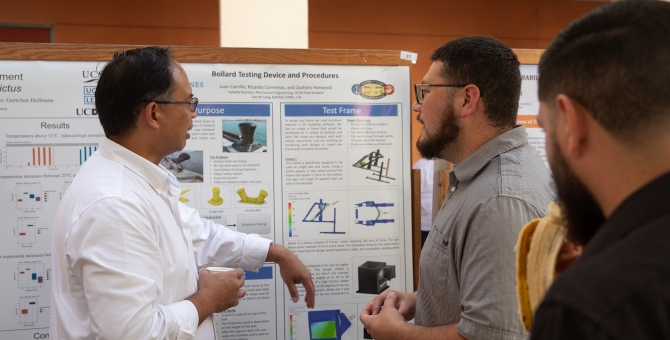

Design of Testing Device and Procedures for Navy Bollards

Project Description

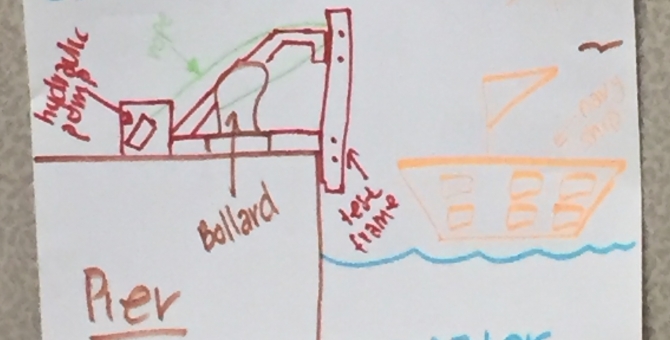

Bollards are short, thick posts that are used to hold ships in place when docked to a pier. They are vital for the safety of passengers and cargo. Over time, these bollards are subject to corrosion and wear, and are recommended to be tested for their strength. Previous testing methods failed to either replicate the steep angled forces or adapt to the various pier structures.

Our project has investigated multiple methods of bollard testing, including nondestructive testing, that allows operators to analyze the bolts for corrosion, voids, and cracks. In addition, we have designed a testing frame to realistically represent the loads that ships apply on bollards. The frame is also designed to be versatile enough to be used on different pier set-ups and bollard geometries. For modeling, we used Autodesk Inventor and ran stress simulations. After identifying major stress areas, refinements were made to the design. Our frame uses two attachments depending on the type of bollard.

To recreate the forces, we are using a pulley system for the shorter cleats and bollards, and a hydraulic cylinder that will be propped up at certain angles for larger ones. We have also formed leg supports that are able to extend past bumpers and other obstacles on the side of the pier. Our design will ensure bollards are tested accurately for their capacity so that if they are not up to standard, they can be replaced and not put lives and materials at risk.